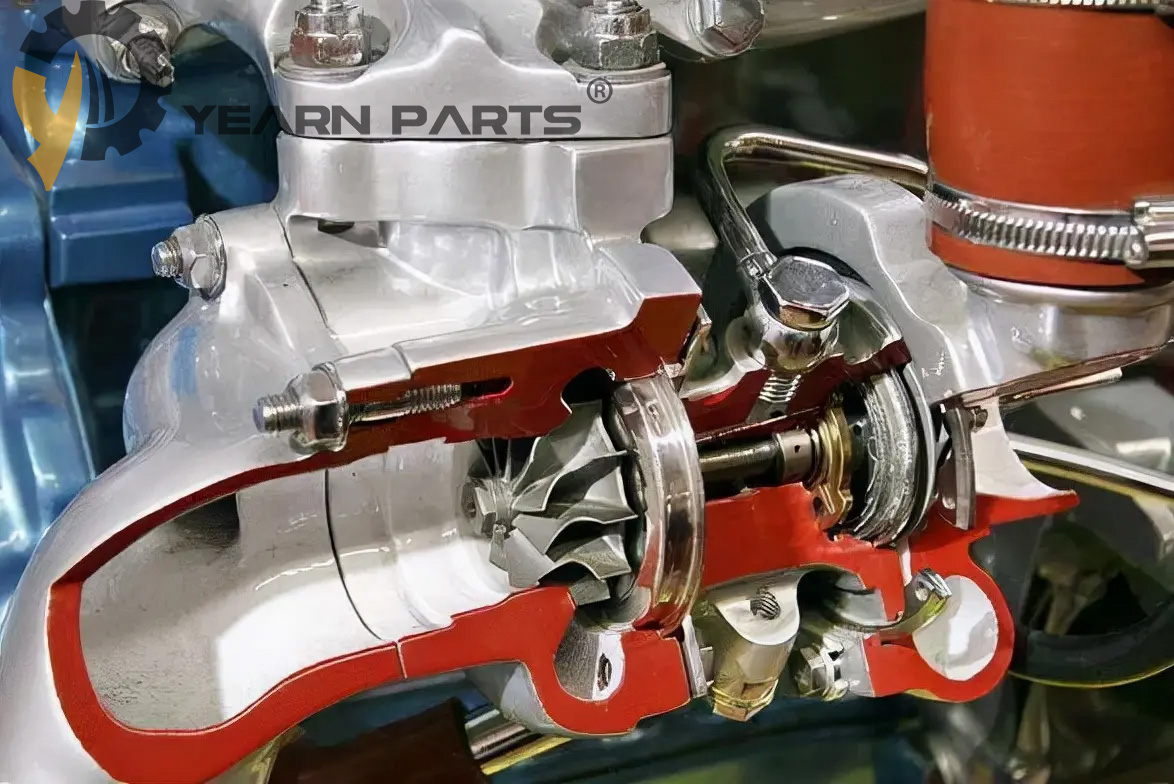

In the realm of automotive engineering, turbochargers have emerged as a game-changer, revolutionizing the way engines perform. These ingenious devices provide a significant power boost to engines, enhancing performance and efficiency.

Read more »Blog

- Posted: May 29, 2023Categories: Technical Support

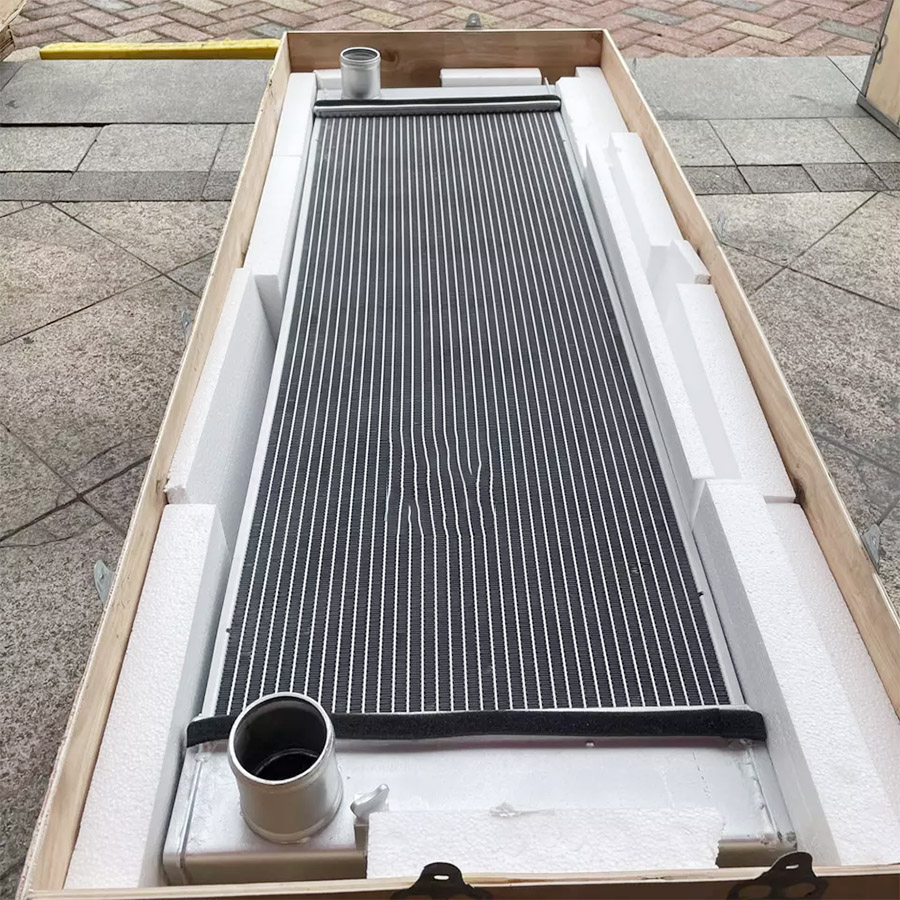

- Posted: April 20, 2023Categories: Technical SupportWater tank radiators play a crucial role in maintaining optimal engine temperatures, ensuring efficient performance and preventing overheating. These essential components are designed to dissipate heat generated by the engine, keeping it within a safe operating range. In this article, we will explore the functionality, benefits, and importance of water tank radiators in the automotive industry.Read more »

- Posted: March 13, 2023Categories: Technical SupportWhen checking the engine, we must remove the air pipe after the engine is turned off and cooled.Turn the impeller in the middle by hand, the impeller normally has a small gap and can rotate smoothlyIf it freezes, it means the supercharger is locked.See what's going wrong, take it off now, we'll take a look after we take out the supercharger.Read more »

- Posted: December 06, 2022Categories: Technical SupportCheck after purchasing: Disassemble all packaging and cover, check random attachment, and save the purchase voucher, qualification certificate and after -sales service card.Read more »

- Posted: November 02, 2022Categories: Technical SupportThe excavator must be maintained frequently on weekdays. If it is not well maintained, its service life will not be long. It is not difficult to maintain the excavator. Here are some maintenance methods for your reference.Read more »

- Posted: January 30, 2022Categories: Technical Support1. The generator does not operate according to the specified technical conditions, such as the stator voltage is too high and the iron loss increases; If the load current is too large, the copper loss of stator winding increases; The frequency is too low, which slows down the speed of the cooling fan and affects the heat dissipation of the generator;Read more »

- Posted: October 22, 2021Categories: Technical SupportRead more »

Welcome to YearnParts,Here is a aticel about us Blog.

We are professional after-sales maintenance technical support and parts replacement for construction machinery parts, here we will update 50 different parts on our website every day and provide professional machine maintenance experience on a regular basis